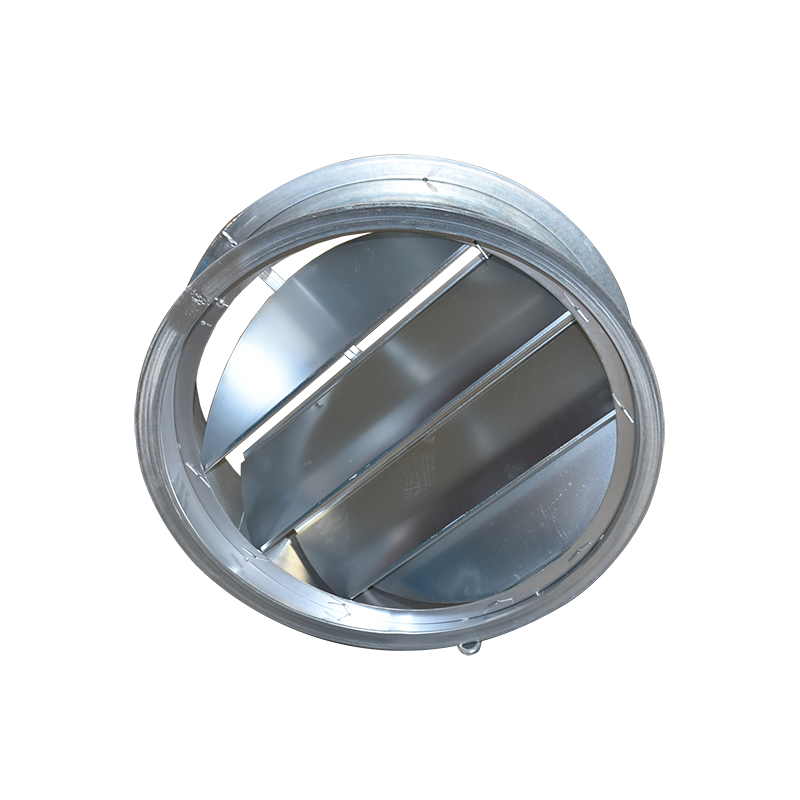

Circular Check Valve

Circular Check Valve

A check valve is a valve with a circular disc as its opening and closing element. It operates by its own weight and the pressure of the medium to prevent backflow. It is an automatic valve also known as a non-return valve, one-way valve, reflux valve, or isolation valve. The disc movement is categorized as lift or swing. A lift check valve is similar in structure to a globe valve, lacking the stem that drives the disc. Media flows in through the inlet (lower side) and out through the outlet (upper side). When the inlet pressure exceeds the sum of the disc's weight and its flow resistance, the valve opens. Conversely, when the medium flows back, the valve closes. A swing check valve has an inclined, pivotable disc and operates in a similar manner to a lift check valve. Check valves are often used as bottom valves in pumping systems to prevent backflow. Check valves can be used in combination with globe valves to provide safety isolation. Their disadvantages are high resistance and poor sealing when closed.

Check valves are also used in pipelines supplying auxiliary systems where the pressure may rise above the system pressure. Check valves are primarily categorized as swing check valves (rotating around the center of gravity) and lift check valves (moving along an axis).

Check valves are designed to allow flow in one direction only and prevent flow in the opposite direction. These valves typically operate automatically: the disc opens under the pressure of fluid flowing in one direction. When fluid flows in the opposite direction, the fluid pressure and the self-closing action of the disc act on the valve seat, shutting off flow.

Check valves, which include swing check valves and lift check valves, are examples of this type of valve. Swing check valves have a hinge mechanism and a door-like disc that rests freely on the inclined seat surface. To ensure the disc always reaches the proper position on the seat, the disc is designed into the hinge mechanism, allowing ample swing space and ensuring true, reliable contact with the seat. The disc can be made entirely of metal or inlaid with leather, rubber, or a synthetic covering, depending on the performance requirements. When a swing check valve is fully open, fluid pressure is virtually unimpeded, resulting in a relatively small pressure drop across the valve. The disc of a lift check valve rests on the valve seat sealing surface on the valve body. This valve is similar to a globe valve, except that the disc can be raised and lowered freely. Fluid pressure lifts the disc from the seat sealing surface, and media backflow causes the disc to fall back onto the seat, shutting off flow. Depending on the operating conditions, the disc can be an all-metal structure or feature a rubber pad or ring embedded in the disc holder. Like globe valves, the fluid passage through a lift check valve is narrow, resulting in a greater pressure drop across a lift check valve than a swing check valve, and the flow rate of a swing check valve is less restricted.